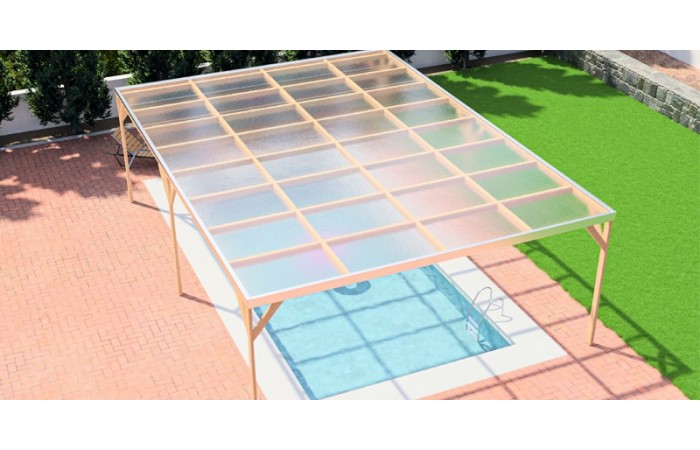

The Complete Polycarbonate Roofing System

Whether you’re building a lean-to or are reviving your conservatory roof, using polycarbonate roofing is the ideal solution. This is due to being wonderfully lightweight and highly durable, all whilst being relatively low-cost.

Building a polycarbonate roof can be a challenge. This is as it is not only the sheet you’ll need, but you’ll also require the compatible trims and fixings. These help to ensure your polycarbonate roofing sheets are secured into place.

Choosing Your Sheets

Multiwall polycarbonate roofing sheets are available in various thicknesses. Each thickness is designed for specific applications, ranging from cladding to carports to conservatories. Ensuring you have the appropriate polycarbonate roofing sheet for your project will help you maximise both durability and insulation.

See below example of which projects each thickness can be used on. Use this as a referenced before ordering polycarbonate roofing sheets and, if you need more advice, contact our team online or by telephone.

4 - 6mm Polycarbonate Sheets

These are ideal for cladding, such as the side panels of a greenhouse. We do not recommend they be used on roofing projects. This is as light debris, such as conkers or hail, may in fact puncture the sheets. 4 – 6mm polycarbonate sheets also provide minimal insulation.

10 – 16mm Polycarbonate Sheets

These are ideal for small roofing projects, such as a carport. Due to 10 – 16mm polycarbonate having multiple walls they are able to withstand small-medium sized debris. The chambers between each wall also provides greater insulation.

25 – 35mm Polycarbonate Sheets

These are ideal for large roofing projects, such as conservatories. With them offering seven walls, they can handle large debris and offer great insulation. In fact, 25mm polycarbonate sheets have a U-value of 1.4W/m2k.

As you can see above 10 – 25mm polycarbonate sheets are perfect for virtually any roofing project. The cost difference between the various thicknesses is also minimal, especially when you consider the added benefits offered by thicker sheets.

Selecting Your Glazing Bars

At the heart of every polycarbonate roofing system are a handful of glazing bars and trims. These are used to secure your polycarbonate panels to your timber frame. They can be found in either PVC or aluminium varieties, with the latter of the two providing additional strength.

Glazing Bar with End Cap

Your glazing bars are at the heart of your roof. It is simply screwed into your timber rafters. You then join the lengths of two sheets by sliding them into either side. Many glazing bars then snap down to snuggly secure your polycarbonate sheets into place, whether they be 10mm or 35mm.

When ordering a PVC glazing bar, you will typically receive three components. These are the head cap, base bar and end cap. If you’re using an aluminium glazing bar the base bar will be replaced by a rubber gasket.

Whilst PVC glazing bars can be used on smaller projects, we recommend aluminium glazing bars are used on projects with a larger sheets and a greater overall span. Aluminium glazing bars should also be used in areas of extreme winds, such as the coast.

Drip Trim

The drip trim is placed at the lowest part of your polycarbonate roofing system, which is usually away from the wall. This does not only allow water to trickle off but prevents any water from entering the chambers.

PVC drip trips are common. When using an aluminium glazing bar system, you will instead use an end-stop bar. It does the exact same job but is used on all sides of your polycarbonate roof.

End Stop

With the front of your polycarbonate finished with the drip trim, you may want to secure the left and right hand sides. For this you will use an end stop bar. This features an additional wing that fits against your timber frame.

H Section

If you’re having to butt multiple sheets up against each other on the width, you would use a H section. This acts in a similar way to a glazing bar, but it does not usually require the support of a purlin. This is unless you have particularly wide polycarbonate sheets.

Fixing Buttons

Fixing buttons are used to fix your polycarbonate roof sheets to your fasters. The large head and foam washer prevent any water ingress. They also features a screw that is appropriately sized and secures itself into your timber rafters.

Flashing Tape

When fitting your polycarbonate against a wall, you may wish to achieve a professional finish with lead flashing. Due to lead being difficult to work with, we offer a lead replacement. This sticks to both the wall and your polycarbonate sheet to stop any water ingress at the top of your sheets. It also provides a beautiful, professional appearance.

Picking Your Timber

Unless you’re using a self-supporting glazing bar system, you’ll require a timber roof batten. As with any roofing structure we urge our customers to use timber that is BS 5534:2014 compliant. This ensure it is of the highest quality and does not pose any risks.

Read our in-depth article on what to consider when buying roof battens, in which we reveal why BS 5534 compliant timber is required and much more. Alternatively, contact our team online or by telephone for further information on timber battens.

Ready to Order You Polycarbonate Roofing System?

With polycarbonate roofing sheets and glazing bars available to order online, you needn’t shop elsewhere. Roofing Megastore are also offering up to 20% off polycarbonate roofing, ensuring you make mega savings.

If you have more questions about polycarbonate roofing, read our mega guide. You can also speak to our team online or by telephone. They will not only answer your product questions, but will ensure you have everything you’ll need for your upcoming project.