Is Aerogel the Best Insulation?

Aerogel is a unique solution in the world of insulation. Though it has been around for decades, only recently has it started to come into the limelight as a wonder insulator. Originally designed for space travel, it boasts one of the lowest densities of any physical material, making it the lightest insulation known.

Contents

- A Brief History of Aerogel

- Why Does Aerogel Make a Good Insulator?

- Pros

- Cons

- Aerogel versus Sheeps Wools & PIR Boards

- Is Aerogel a Good Choice for My Home?

A Brief History of Aerogel

You may think that because Aerogel is one of the lightest materials to have ever been made (in some cases being 99.5% air), that it is a modern innovation. But, this simply isn't true. In fact, it was invented almost a century ago in the early 1930’s by Steven S Kistler who, trying to prove that solid gel and wet gel had the same shape and size regardless of their state, figured out a way to remove the liquid from the gel and replace it with gas.

This liquid, being the heaviest part of the gel, once removed left the material far lighter but without harming its integrity. This unique composition meant that a block of aerogel as large as an average human would weigh less than 1 pound but support up to 1000.

Another property that aerogels were found to have been a superb thermal insulator. And when we say superb what we really mean is best with a k-value as low as 0.013 W/mK. The lowest thermal conductivity of any known solid.

So not only is it incredibly lightweight and strong but it also boasts extraordinary protection from extreme temperatures. The kind you might find on Mars. This is why, in 1996, aerogel was the insulation material of choice for the Pathfinder Rover and was subsequently used again for the follow-up rovers in 2003.

Why does Aerogel Make a Good Insulator?

So, why is it that this material that’s so much lighter and thinner than wool or PIR boards can provide a significantly lower thermal conductivity? Well, bear with us while we dive into the physics of the matter.

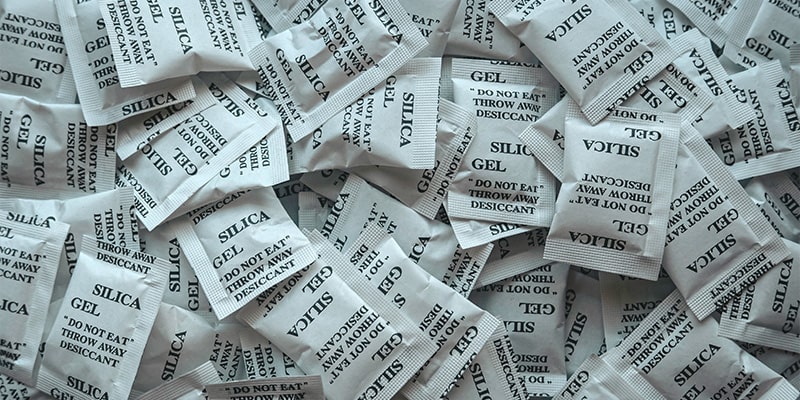

The gel that aerogel is most commonly made from is silica. Yes, the small beads that sometimes come with your Amazon packages. The solid of this gel, the part that keeps aerogel stable when the liquid is removed does so because it is comprised of minute, intertwined three-dimensional clusters.

These clusters are so stable that only a very small percentage of them is needed to maintain the integrity of the gel. Everything else is air inside the microscopic pores of this solid. Because the air is so tightly packed in there is very little room for it to move – preventing both conduction and convection.

In essence, neither heat nor cold are able to efficiently make their way through the material as they are very literally trapped by the air.

Pros

Lightweight & Easy to Install

Aerogel’s preeminent feature is its weight. Boasting the name of ‘lightest solid on earth’ it is easy to transport vast amounts of it at once, easy to install and suitable for use in just about any structure without having to worry about altering the frame to bear additional weight. This also makes it one of the simplest materials to install.

Superb Thermal Insulation

Aerogel is indisputably one of, if not the most, thermally efficient materials ever created. Having been used to insulate spacecraft on Mars, it is more than capable of outperforming most common insulation today. Offering perhaps the greats savings you could enjoy on emissions and energy costs.

Hydrophobic

Like many other modern insulators, aerogel also possesses hydrophobic properties. This means it is equally efficient at repelling water as it is heated. This makes it the perfect choice for applications with less space to insulate – where you wouldn’t normally have room for a separate waterproofing layer.

Durability

As you’d expect from a material used to protect rovers on Mars, aerogel is also surprisingly hardy. Despite being mostly air, it can maintain its shape in high-temperature environments in excess of 100°C without shrinking, warping or cracking. Similarly, it also shrugs off impacts and vibrations with little effort.

Cons

Expensive & Difficult Manufacturing

The biggest challenge holding Aerogel back is that we’ve yet to perfect its manufacturing. As you’d expect, removing water from silica gel and replacing it with air required specialist equipment and whilst advancements have made this process more reliable they are still far from perfect. This makes producing the insulation in large volumes a hurdle that still needs to be overcome.

One big caveat worth mentioning, however, is the environmental benefits of overcoming this hurdle. Insulation, after all, is not the only use of aerogel. Studies commissioned by the European Parliament have found that strengthened aerogel could be used as an alternative to cement for certain applications. Manufacturing these ‘X-aerogels’, they found, could reduce emissions produced by heating and cooling in cement manufacturing by as much as 42%. This a big dent considering estimates list Portland cement as an 8% contributor to global CO2 levels.

Cost

High performing and difficult to produce, it’s no wonder that Aerogel has as a high price tag as it does. Unfortunately, this too makes it a less than-practical choice for many. For £90 you can around a 12 x 12 cm blanket of Aerogel, compared to 13 meters of sheep for the same price.

Fragile Under Tension

Whilst Aerogel is unmistakably strong under the right conditions, it can also be very brittle under tension. If the material is stretched it can snap, meaning it cannot be stretched. Being so inflexible can cause issues in more complex applications.

Aerogel versus Sheeps Wools & PIR Boards

We’ve picked out natural insulation and common, high-performer, PIR but in truth, you can compare aerogel to most modern insulation materials in a similar manner. Using the 3 big factors that come into play when looking to buy. Thermal performance, ease of installation and, of course, price.

As for ease of installation, all three can be installed safely with limited protective equipment on a DIY basis. With the exception of aerogel needing a tad more care, due to its brittle nature, both it, sheep's wool and PIR boards can be argued to be on the same level. As for price and performance, we’ve put together a table of rough comparisons for you below:

|

|

Thermal Conductivity (W/mK) |

Price |

|

Aerogel |

0.015 |

£120 (1200 x 1200mm) |

|

Sheep’s Wool |

0.039 |

£90 (50 x 370mm x 13m) |

|

PIR Boards |

0.022 |

£32 (2400 x 1200mm) |

*Subject to change depending on specific product

Is Aerogel a Good Choice for My Home?

With all of this in mind, we have a good basis to answer the question of whether or not aerogel is a suitable replacement for your wall and roof insulation.

Whilst it is true that aerogel, looking at the numbers alone, is the far superior insulator, many other factors make it a less than feasible choice for residential applications. The price and availability alone disqualify in many cases, with it being simply a case of other materials being more than adequate to meet current building standards. To make a long story short, with current aerogel products, you likely wouldn’t notice the extra cost once installed.

Commercial and Industrial applications, however, are another story. In warehouses and other large Industrial complexes requiring specific temperature control, it can be a perfect choice. Beyond buildings aerogel can be used in windows, replacing typical argon glass as well as jackets and coats.

Perhaps most surprisingly, cotton aerogel has also been found to be a fantastic haemorrhage control device. Put into a bleeding cut it can apply pressure and cease bleeding far more effectively than a bandage.