How to Fix Box Profile Roofing Sheets

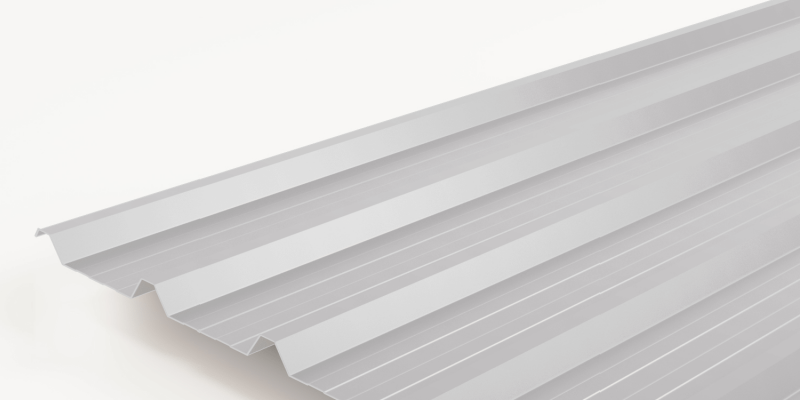

Box profile roofing sheets are some of the sturdiest roofing materials on the market. Whilst they aren’t frequently used on houses, they’re often seen atop structures such as stables, garages, and garden outbuildings such as sheds.

They also frequently see use as siding on industrial or commercial structures such as warehouses, where steel cladding helps to achieve a clean, industrial aesthetic. These sheets offer fantastic strength thanks to their unique profile, along with their galvanised steel construction, which provides a long lifespan coupled with impressive impact resistance.

One of the most important ways in which you can maximise your roof’s lifespan and ensure it performs to its fullest potential is correctly fixing it to your roof. This guide provides an overview of how to be sure that your new box profile roof sheet is applied properly, taking you step-by-step and answering common questions from customers about fixing box profile roofing sheets.

How to Install Box Profile Roofing Sheets

There are a few things you’ll need to consider before fitting your box profile roof sheets. First, ensure that your roof structure is sound and able to support the sheets, with joists and beams installed ready for the sheets to be placed on top. Secondly, you’ll need to be sure that your sheets are the correct size. We offer made to measure roofing sheets including box profile, pantile, and more, to allow you to get the exact size you need with minimal fuss. However, this is not always possible.

How to Cut Box Profile Roofing Sheets

Firstly, we’d recommend double-checking the measurements of your roof, and of the box profile roofing sheets you’ve purchased e.g. 34/1000 Box Profile 0.7 Thick Sheets, to make sure that cutting them is necessary, and to check how much you need to cut.

You should always perform work like this at ground level, with the sheets face down on a flat surface, ideally raised off the ground by padded supports. This is for your own safety, and reduces the risk of causing damage to the sheets.

- Once measured and double-checked, mark out the line you’d like to cut using a marker pen and straight edge.

- Using a tool that generates as little heat as possible, such as a cold cutting circular saw with a fine-toothed blade, carefully cut along the marked line.

- If you need to make any smaller cuts, or more precise cut-outs that aren’t simple straight lines, you could consider using a jig saw or reciprocating saw.

- Once you’ve cleanly cut through to the other side across your marked line, rub along the cut edge with an emery cloth to smooth it out.

As always, if the above process is new to you, or you don’t feel comfortable carrying it out yourself, there’s no shame in consulting a professional. Whilst this will add to project costs, it ensures that the job will be done quickly, safely, and to a top standard.

Laying Box Profile Sheets

The way to lay these sheets is to first start at the corner of your roof, next to the eaves. Place the sheeting away from the direction of the wind to prevent uplift whilst you’re working. If you don’t place the first sheet perpendicular to the eaves and ridges, it will create an unsightly saw-tooth appearance that will make your roof look untidy.

Always overlap each sheet by at least one corrugation (or “side lap”), or more for added water resistance. However you choose to overlap your box profile roof sheets, be sure to accommodate for this when planning and purchasing sheets for your project. The first row of box profile sheets should run over and beyond the top of the structure wall to shed rainwater more easily, ideally into a gutter.

In addition to the overlaps, we’d recommend using both lapping tape and stitching screws for an added weathertight seal. For side laps, this lapping tape should run along the crest of the profile to be lapped, along with screws at 600mm intervals to ensure maximum security. For end laps, overlap sheets by a minimum of 250mm, supported by a purlin. Lapping tape should be used here once again across the whole width for the tightest seal possible.

Fixing Box Profile Roofing Sheets

Once you’re happy with how your sheets have been laid, it’s time to seal the deal by fixing them to your roof. There are a few things to keep in mind:

- Choosing the right fixings: Many different fixings are available for box profile sheets, and the right one depends on what your purlins are made of. However, most manufacturers make their fixings to be highly versatile, and provide clear guidance about where they are and aren’t suitable. Some fixings are also designed for use on different parts of the sheeting, with some being shorter and intended for use lower down, whilst longer fixings are available for use towards the apex of your roof.

- Correctly spacing the fixings: Box profile roofing sheets are usually fixed in the troughs of the sheets, however it’s not usually necessary to place fixings in every trough. In general, they should be placed in troughs 1, 3, 4, and 6, but towards the bottom of the sheets and the eaves of your roof you can fix all six troughs to prevent wind uplift.

- Using the Colour Fixing Caps: Most fixings for box profile sheets will either have colour caps provided or available to buy separately. These caps are a fantastic accessory which help to keep the fixings protected against the elements. Plus, these rubber caps come in a number of colours, allowing them to blend into or contrast against your box profile roof, whichever aesthetic you’d prefer!

The final step in fitting a box profile roof is laying and fixing the ridge caps. This is of course optional depending on the type of roof you have. These ridge caps should be laid against the prevailing wind, overlapping one another by at least 150mm. Stitching screws should be placed at the top of each profile covered, along with ridge filler for an extra weathertight seal, which will also keep out birds and other pests.

Conclusion

You should now have a beautiful, fully fixed box profile roof. We stock a fantastic range of box profile roofing sheets from leading brands, favoured by qualified professionals and homeowners alike. If you’ve got any more questions, please get in touch with our customer service team via telephone on 01295 565 565, email on sales@roofingmegastore, or our handy live chat service.