The Mega Guide to Corrugated Roofing Sheets

Corrugated roofing sheets are some of the most common means of waterproofing for garages, sheds, carports, and larger agricultural buildings. Beyond being one of the easiest forms of roofing to install, these sheets tend to be far stronger, more lightweight, and longer-lasting than most alternatives. In fact, corrugated sheets are so popular that their innovation and improvement hasn’t really stopped. Now available in a huge range of materials and profiles to choose from, they are perfect for almost any project, DIY or otherwise.

However, we know that choosing from this large selection of products can be a challenge, which is why we have put together this comprehensive guide. Not only will we cover the types of roofing sheets available, their benefits and their uses but will also explain how these sheets are installed and with what flashings and fixings, allowing you to shop with confidence.

Table of Contents

Choosing Your Corrugated Sheets

Corrugated roof sheets are a common sight up and down the UK and right across the globe. They’re incredibly popular as a roof covering for all sorts of structures, and can even be used as a low-cost, durable alternative to UPVC cladding.

Whilst our corrugated roofing range is extensive, this guide is going to speak about five of our most popular materials; Bitumen, Metal, Polycarbonate, PVC, and Fibre Cement.

Bitumen

Bitumen corrugated roofing sheets are manufactured from fibres that have been saturated in bitumen (the same material they use to pave roads). This construction is what gives these sheets their high tensile strength at a lightweight. Due to this, they are suitable for many different applications, including garages, sheds, summerhouses, carports, stables, shelters, and many other outbuildings. Created by leading brands Onduline and Coroline, these sheets are available in a wide selection of colours.

Metal

As with all forms of corrugated sheeting, the undulating design allows for effective drainage as well as increased impact resistance. This outstanding strength is shown most prominently in metal corrugated roofing sheets. Thanks to their aluminium or galvanised steel construction, these sheets are both relatively lightweight and incredibly strong. As a more ‘heavy duty’ option they are much more suited to larger commercial and agricultural builds like warehouses or barns and, in some cases, can last up to a hundred years.

Polycarbonate

Polycarbonate is an extremely strong material, with corrugated polycarbonate sheets being virtually unbreakable and resistant to damage from UV rays. This means little to no degradation or discolouration over their decades-long lifespan. As they are produced from plastic, these sheets are also far more flexible than bitumen or metal, which allows them to be used on roofs with more complex designs. What’s more, thanks to their clear finish, these sheets provide excellent light transmission, perfect for conservatories.

PVC

PVC is similar in many ways to polycarbonate. Both materials offer a lightweight, shatterproof alternative to glass panelling, making it far safer. What’s more, corrugated plastic roofing are highly waterproof, and are cheaper than polycarbonate whilst also providing excellent levels of light transmission. The main drawback to PVC however, is its impact resistance. PVC is weaker than polycarbonate and may become damaged during severe weather. PVC roofing can also only be expected to last around 10 years.

Fibre Cement

Corrugated fibre cement roofing sheets are incredibly versatile, and offer a number of fantastic benefits over other materials. These sheets feature a reinforced composite construction, which makes them incredibly strong. What’s more, they’re immune to rust, rot, corrosion, and many other things which often plague roofing. Plus, fibre cement offers breathability, along with excellent thermal and acoustic insulation. This makes them perfect for both agricultural and industrial structures.

Installing Corrugated Roofing

Fitting corrugated roofing is surprisingly pain-free, whether you’re a DIYer or a qualified professional. Most brands that manufacture corrugated sheeting also provide specially made fixings and flashings to accompany their products. Whilst installing corrugated roofing made by each brand can be a little bit different, they share many things in common. As always, refer to the manufacturer’s installation guide to maximise the strength and longevity of your roof, and prevent voiding your warranty.

Safety Considerations

Regardless of the size and scale of your project, safety should always be taken into consideration. The Health and Safety Executive offer a lot of advice for this, and reiterate some of the key points to keep in mind. You should ensure that beyond wearing your own protective equipment (rigging gloves, steel capped boots), any ladders, scaffolding or other rigging is suitable, stable and strong enough to bear the loads you need them to. Fitting a new roof, with maybe the exception of a shed, should always be undertaken by at least two people, and any dangerous kit should be kept well away from children when working on a DIY job.

Fixings and Flashings You’ll Need

- Screws/Nails: Fairly self-explanatory, these fixings are should be installed at the peak of the corrugations at 200-300mm centres.

- Eaves Filler: These are designed to fill the gap between your eaves and sheets which is created by the corrugations undulating design.

- Wall Flashing: As the name suggests, this flashing should be used when your roof sheets abut a wall and will provide a finish that prevents the entry of water.

- Ridge Cap: This will be a separate product designed to cover the ridge of your roof. Typically, this will include an overhang which can be fixed to the tops of your sheets.

- Verge: Like the Ridge Cap, this will be a component used to finish the sheets where your roof meets the gable.

Tips for Fixing Corrugated Roofing

- When purchasing your sheets, try to order flashing and fixings of the same brand. This will guarantee that every part of your roof system will be compatible.

- When storing non UV-protected sheets outside ensure they are covered by a tarpaulin to protect them from direct sunlight that may cause cracks or distortions.

- Try to avoid fitting on particularly windy days as sheets can be blown away and damaged. This is particularly true for lightweight PVC sheets.

- Avoid cutting PVC in cold weather as this may cause severe damage. These sheets should be stored in a warm room for 2-4 hours before cutting.

- Before drilling holes in your sheets, arrange them on your roof loosely and mark any hole positions with a felt tip pen. This will help to avoid any mistakes and wastage.

How to Install Corrugated Roofing

What You’ll Need:

- Tape Measure

- Circular Saw/ Hand Saw

- Drill

- Straight Edge

- Necessary Fixings and Flashings for your system

1. Determine the necessary overlap and overhang

One of the reasons corrugated sheeting is designed in a ‘wave like’ pattern is so that adjacent sheets can easily overlap with one another.

The length of this overlap will depend on the pitch of your roof, which should be detailed in your manufacturer’s guide. An overlap of 150mm is often recommended for roofs with 10° pitches, whilst 300mm is recommended for 5° pitches.

Always allow for an overhang of at least 60-70mm so that water can run off without coming into contact with rafters or purlins, which can lead to damp and structural weakness.

2. Cut the sheets to size

Measure the length of your rafters and the distance between them. This should give you an area size for the sheets to be cut to. Depending on the material of your sheet you may need to use either a circular saw or hand saw. Either way, the sheet should be secured to a workbench so that you can get an even cut.

3. Determine the overlap direction

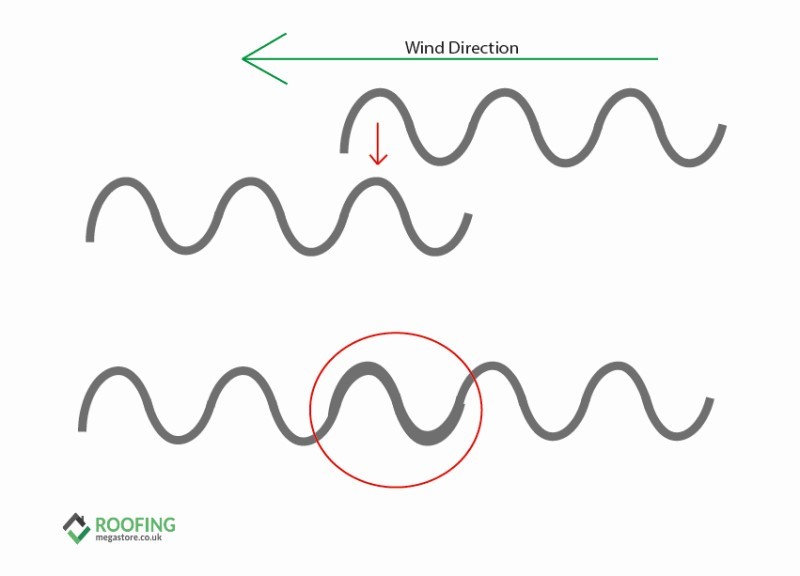

The overlapping of the sheets should be done in the direction of the wind. For example, if the wind is blowing from the east, the sheets on the left should overlap those on the right. This will prevent wind from blowing your sheets apart during the installation.

4. Fix the first sheet to your purlins

Align your first sheet at the edge of your roof, ensuring that the necessary overhang is maintained. Then, fix your screws or nails through the corrugation and into the purlin. These should be run vertically and not overtightened.

5. Fix the remaining sheets

The rest of the sheets can then be fixed. Remember to overlap each sheet with the one before it and secure using vertical fixings.

6. Add Flashing

Some flashing pieces will be similarly be corrugated and as such can also be overlapped with your sheeting. Flashing should be installed at the ridge, eaves and at any point where your roof abuts a wall.

Extra Tips When Installing Corrugated Roofing

- When purchasing your sheets, try to order flashing and fixings of the same brand. This will guarantee that every part of your roof system will be compatible.

- When storing non UV protected sheets outside ensure they are protected from any direct sunlight that may cause cracks or distortions.

- Try to avoid fitting on particularly windy days as sheets can be blown away and damaged.

- Avoid cutting PVC in cold weather as this may cause serve damage. These sheets should be stored in a warm room for 2-4 hours before cutting.

In Closing

Now that you’re ready to go ahead with your project, the only thing left to do is order your sheets and get to work. Take a look at our corrugated roofing range. Thanks to mega savings and our nationwide delivery network, your project will be kept on-budget and your materials could be with you in a matter of days. Plus, thanks to our price-match promise, we won’t be beaten on any like-for-like quote.

If you’ve still got any questions, get in touch with our award-winning customer service team. They’ll be able to help you get your project underway as soon as possible. Call them on 01295 565 565, email [email protected], or use our handy online live chat.

Please note: This article has been written for information purposes and we therefore take no responsibility for any purchasing decisions you make or installation processes you follow as a result of reading this article. Whilst we act as a retailer, we are not experts nor qualified in the installation of corrugated roofing sheets or any other roofing material. We therefore recommend that you refer to your manufacturer's guide and, if appropriate, consult a qualified professional.